Quality Management

/

Striving for Pharmaceutical Excellence Through Quality Control

Quality Policy : Kureasia Pharma Pvt. Ltd.’s manufacturing facilities meet stringent GMP norms, laid down in the “Revised Schedule M” by the Drug Controller (General) India, Ministry of Health, and Government of India. The GMP and GLP certifications of our manufacturing facilities authenticate our compliance with international standards. Our products are quality tested at every step of our process from manufacturing to packaging that proves their excellence and effectiveness.

Call Us – +91 93110 19560

Quality Control

Our in-house state-of-the-art testing laboratory is fully equipped with the latest pharmaceutical lab apparatus. We have a highly qualified and experienced technical team, who use transparent, traceable and calibrated techniques to maintain high standards of quality at all stages of the manufacturing and delivery process.

Our quality control (QC) laboratory plays a critical role in pharmaceutical production, for both in-process and finished product testing. We at Kureasia not only monitor and control the quality of incoming APIs (active pharmaceutical ingredients), but other supplies used in the manufacturing process; QC Labs are also instrumental in the batch release process.

We at Kureasia Pharma, have installed huge Walk in Stability Chambers along with other Stability chambers for conducting stability analysis of the products by determining the stability of our products different temperature and humidity conditions.

We operate in total compliance with the GMP norms set by the WHO (World Health Organization) and the latest international guidelines set by the competent authorities. These norms are adhered by our laboratories listed below:

Chemical Laboratory: - Has a highly-qualified technical team and well-laid out Standard Operating Procedures (SOPs) for operations.

Instrumentation Laboratory: – The fully equipped QC department has the latest lab equipment, such as HPLCs, UVs, TOC, and Walk in Stability Chambers & Incubators among other instruments.

Microbiology Laboratory: – We have a dedicated Microbiology laboratory designed as per ISO 7 norms to ensure cleanliness and adherence to international standards. Separate Media storage, media discard, and pathogen and culture passivation rooms are available to ensure adherence.

The products are subjected to a series of microbial tests during production and post production. The environment and utilities are continuously monitored on a real-time basis here.

The laboratory is fully equipped for

- Physical Analysis.

- Qualitative & Quantitative Analysis.

- Chemical Analysis.

- Stability study Analysis .

- Micro-biological Analysis.

- Effective controls of process.

- Water Analysis.

Our capabilities are, but not limited to

HPLC SECTION

STABILITY SECTION

WATER SYSTEM

Quality Assurance

Our Quality Assurance (QA) Department adheres to strict the highest standards of SISPQ.Our Production team follows clear and precise working instructions for each process activities and operations duly verified by adhering to the Standard Operating Procedures (SOPs) that are reviewed by Quality Assurance qualified personnel and Approved by Head QA. Approved SOPs are available for all critical activities carried out at our manufacturing facility. Implementation and compliance are the responsibilities of individual department heads and Quality Assurance Department.Sampling of Raw Materials and Packing Materials done by trained personnel from QC department, In-Process, Bulk and Finished products are performed by the qualified and trained personnel from QA department.

Call Us – +91 93110 19560

Control at all stages of the manufacturing and packaging processes is maintained by the Quality Assurance Department through strict enforcement of cGMP’s standards. Similarly, all equipment and system qualification and validation are designed and reviewed by suitably trained and qualified personnel before the final approval by Quality Assurance Head.Stability Studies & DocumentationWe at Kureasia Pharma, have installed huge Walk in Stability Chambers along with other Stability chambers for conducting stability analysis of the products by determining the stability of our products at different temperature and humidity conditions.

Air Quality

- Conformation of each processing stage with class of cleanliness; viz. 100, 1,000, 10,000, 100,000 with respect to room air changes, pressure, particle count, flow direction etc.

- Dispensing of raw materials done under reverse laminar air flow stations for product and operator safety.

- Fresh filtered air is provided for non critical areas

- Temperature & Relative Humidity control in classified critical & non critical areas.

- Performance Validation of Air conditioning & Ventilation systems in annual basis

- Regular & Continuous Air quality sample testing

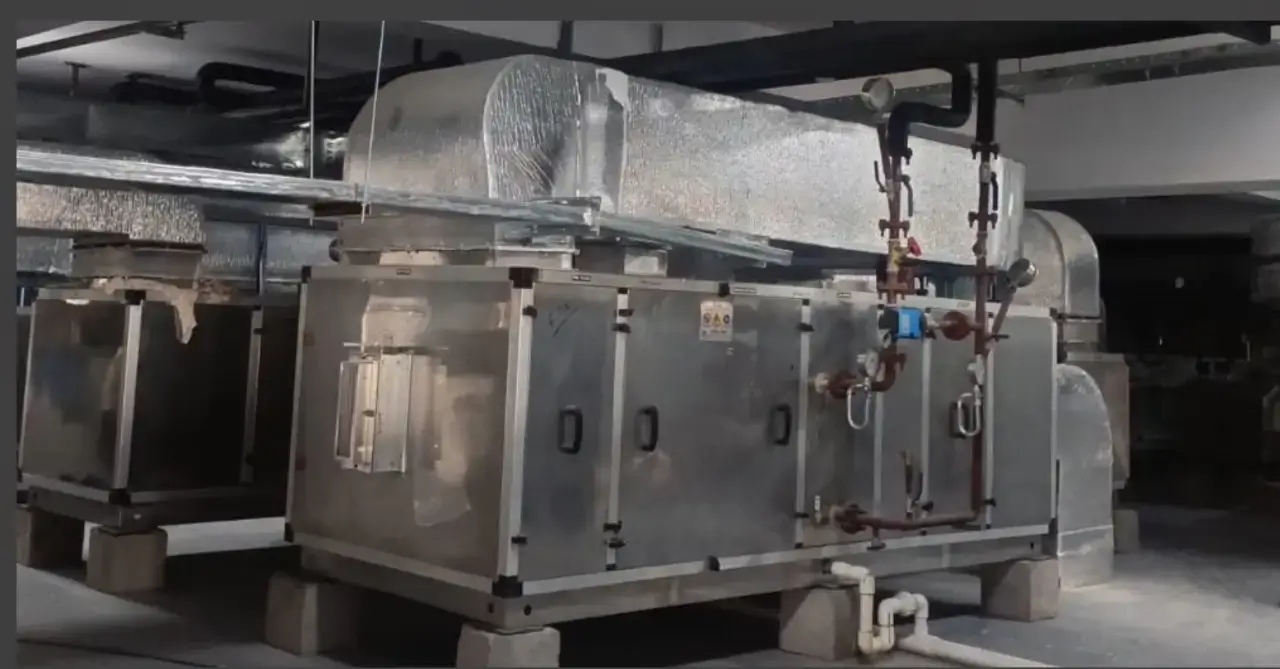

- Controlled indoor air facility with Dedicated AHUs & Dehumidifiers.

- Custom Built Stainless steel AHUs to avoid corrosive effect.

Call Us – +91 93110 19560

Health & Safety Policy

- Commitment to create, maintain and promote an environment conducive to health and safety of all employees.

- Formed Health and safety committee with representatives from management and employees under the chairmanship of director.

- Firs Aid center is operational inside the factory.

- Employees are advised and encouraged to report any illness or incident.

- Pre-employment medical check up is done to ensure all employee free from contagious diseases. medical records are maintained.

- Annual medical checkup is done for employees

- In-house laundry (washing, drying & pressing) facility available as per pharmaceutical Industrial grade to provide the correct level of decontamination, drying and sterility for garments.

Water Quality

Purified Water Generation, Storage & Distribution system:

- A high-purity industrial process water generation system of 5000 LPH capacity is installed with a continuous circulation loop till user points.

- Purified water plant uses media filtration, softening, reverse osmosis & and de-ionization (EDI) processes to produce high-purity water complying with IP standards.

- Purified Water Storage Tank of 3000 Liter with Accessories, Jacketed Storage Tank with Rockwool insulation, and SS 304 Cladding for PW. Chemical analysis on a regular basis as per IP.

- Sampling done from multiple points for microbiological quality.

- Plant sanitized as per predetermined frequency and sanitization reference to system document.

Let’s Discuss Your Requirements

Your Trusted Pharma Partner—From Formulation to Fulfillment

Join hands with Kureasia Pharma’s advanced production line for tablets, syrups, ointments, and more.

Copyright © 2025 Kureasia Pharma | Developed by OTD